JOHN DEERE - 4200 Back

JOHN DEERE COMMANDCENTER DISPLAY 4200

OVERVIEW

Available factory-installed on 6R, 7-210R and 7-230R Tractors

Comes with documentation in base price

Easily add and change features as your needs change

Permanent, non-transferable AutoTrac activation optional

FEATURES

GET STARTED EASIER WITH JOHN DEERE PRECISION AG AND THE 4200 COMMANDCENTER

The 4200 CommandCenter ships from the factory with these three features included with the display and machine purchase so that you can easily take the first steps on your precision ag journey:

AutoTrac guidance

Documentation

Data Sync

Combine the display with a StarFire Receiver, and you are ready to get started with automated guidance by creating maps showing work completed and, if you have JDLink, wirelessly sending your data to the John Deere Operations Center. If you dont need automated steering, you can deduct AutoTrac when ordering your machine. If you want to do even more, you can add a 4200 CommandCenter Section Control Activation for precision control of crop inputs.

NOTE: You will need an AutoTrac activation to use the Section Control functionality with a 4200 CommandCenter display.

WHY 4200 COMMANDCENTER IS THE RIGHT TOOL FOR THE JOB

Sometimes a job on the farm does not require intense Precision Ag management practices. When this is the case, the 4200 CommandCenter is just the tool for the job. The 4200 offers the ability to run core Precision Ag features like AutoTrac guidance, Documentation, Section Control, and Data Sync.

There are two levels of activations that can be ordered on the 4200. The first is the CommandCenter AutoTrac Activation, enabling operators to consistently drive the same guidance path pass to pass. The second is the 4200 Section Control Activation plus CommandCenter AutoTrac Activation. This combines the ability to use AutoTrac on a machine with the value of Section Control, eliminating overlap on critical field operations.

Data Sync enables operators to automatically send data to John Deere Operations Center. Producers can analyze the data from completed fields or view where field work is in process, making it easier for them to make operational decisions. Data is available to analyze through the John Deere Operations Center from any internet-connected device, allowing producers to make important production decisions and giving operations the ability to invoice work recently completed.

TAKE ADVANTAGE OF THE G5 COMMANDCENTER DISPLAY, DESIGNED FOR EFFICIENCY

The G5 CommandCenter was designed to provide a consistent user experience by providing full screen viewing of more run page modules, shortcut keys, and precision agriculture capabilities.

Expect easier setup, along with increased operator confidence thanks to a simple, customizable interface. The improved design of the G5 CommandCenter also aids in an optimal operating experience and maximizes uptime.

In order to increase your efficiency, take advantage of the following features offered by the G5 CommandCenter:

LAYOUT MANAGER:

Easily create page views that meet user needs and that are also equipped with default run pages.

LANGUAGE AND UNITS:

Easily switch between languages with the option to set the active and alternate language. Configure the shortcut bar to include the language toggle allows different individuals to easily switch the display between languages.

USERS AND ACCESS:

Users and access allow the owner or manager to lock out certain functions to prevent operators from accessing or changing settings. Lock-out functions are managed with a defined pin for the administrator.

The G5 CommandCenter can be set to one of two profiles, administrator or operator. The administrator profile is always set to the full access group. This group allows unlimited access to all the features and can lock and unlock features in the operator profile.

MACHINE MONITOR:

The Machine Monitor application provides you instantaneous readings about the status or condition of your machine.

This application shows parameters such as engine speed, coolant temperature, and ground speed.

WORK MONITOR:

The Work Monitor application displays performance information about the task being performed by the machine.

You are shown averages, totals, and productivity of the machine, such as area worked, average working speed, and fuel usage.

Work set up places the settings needed to properly setup features such as AutoTrac guidance, Documentation, and Section Control in a single location. Settings include:

- Client, farm, and field

- Crop type

- Machine and implement dimensions

- Variety/hybrid and planting/seeding rates

- Variable rate prescriptions

- Product and application rates

- Application rates through the implement screens

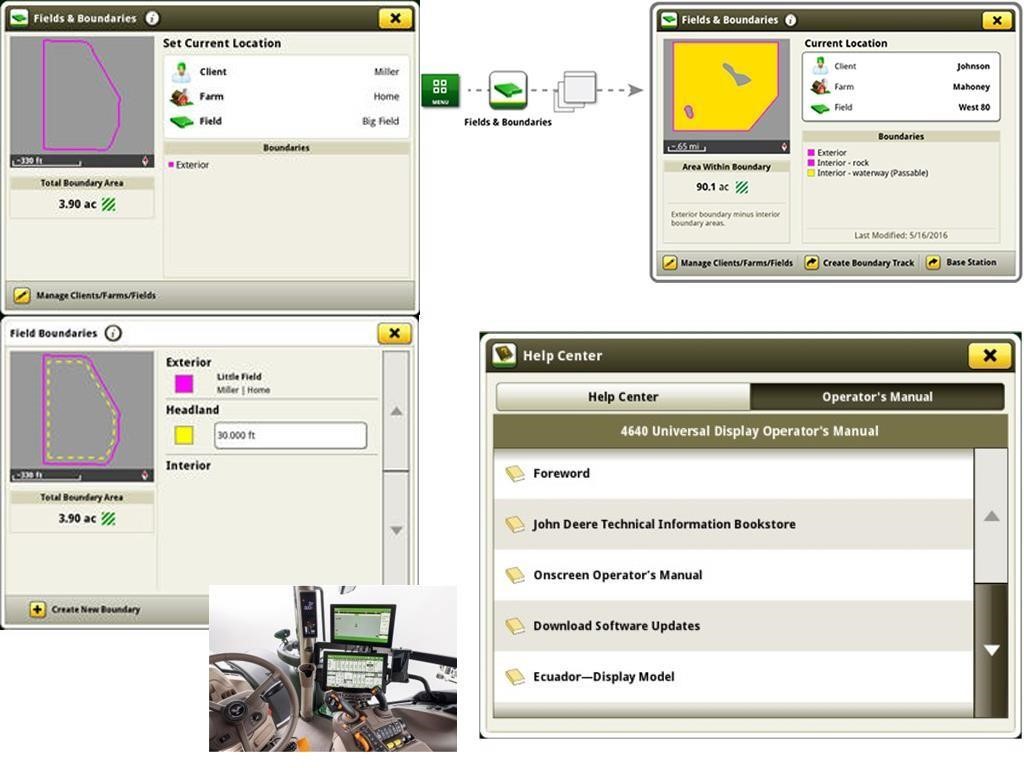

OPERATOR'S MANUAL:

Stay up to date on the latest G5 features and enhancements with the Gen 4 Operators Manual at the users fingertips. With each bundle update, the G5 display automatically receives the latest G5 Operators Manual which means less time locating a paper copy and ensuring the most up-to-date information is always available.

FIELD BOUNDARIES:

Manually drive field boundaries with the G5 CommandCenter or import existing boundary information from the GreenStar 3 2630 Display or John Deere Operations Center. G5 documentation data can be used to create boundaries from coverage within the John Deere Operations Center.

AUTOMATIC BASE STATION SWITCHING:

Producers using John Deere RTK Radio 450 or 900 can link a base station to a desired client, farm, or field. This allows automatic switching to the associated base station when changing fields. The ability to import base station assignments into Operations Center and send back to machines will be available at a later date.

DUAL-DISPLAY MODE:

G5 CommandCenter may be configured to run with the following John Deere displays connected at the cornerpost of a John Deere tractor:

GreenStar 2 1800 Display

GreenStar 2 2600 Display

GreenStar 3 2630 Display

4640 Universal Display

4240 Universal Display

G5 Universal Display

NOTE: Vehicle applications are always located on the G5 CommandCenter.

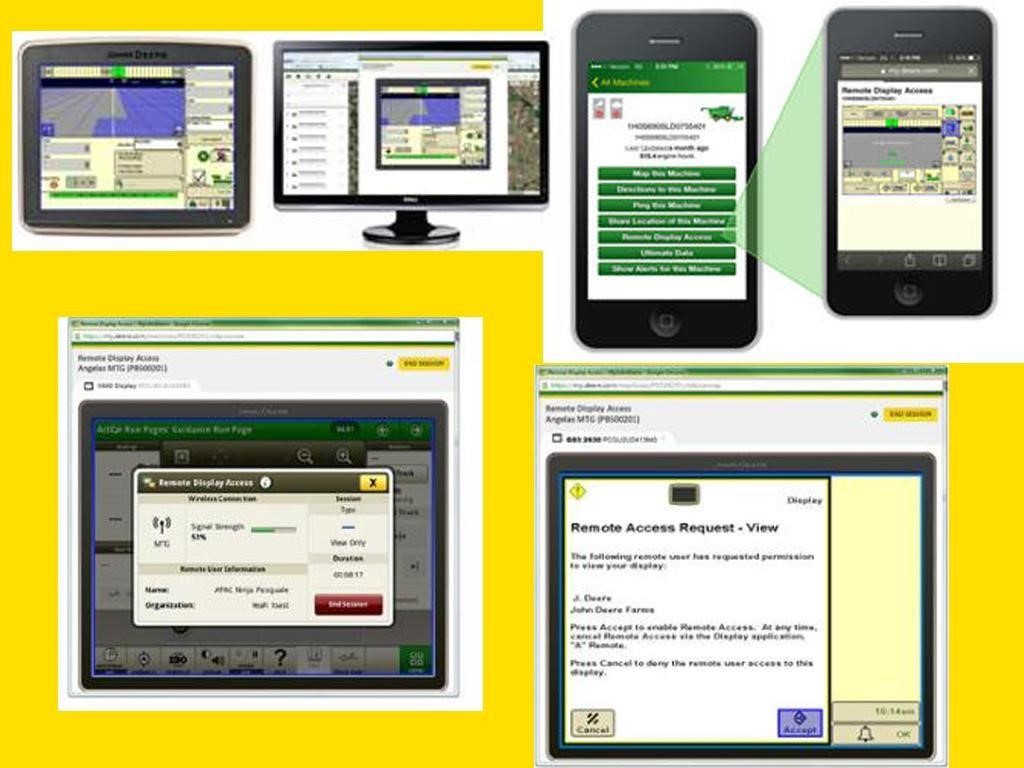

REMOTELY VIEW MACHINE INFORMATION WITH REMOTE DISPLAY ACCESS (RDA)

The ability to remotely view the machines settings, performance, yield, acres, and other information is highly valuable when managing or supervising an operation. It is imperative that your equipment keeps running productively and that you are enabled to provide remote support to improve the quality and efficiency of work while saving time and money. RDA enables you to get help with machine settings or identify a problem and receive assistance in navigating through the steps needed to resolve the issue.

Value of RDA:

Improved confidence in precision farming applications for all operators

Increased productivity with quicker problem resolution

Improved service from John Deere dealer and support personnel

Increased profitability by keeping equipment moving

Reduced labor and travel costs

With the 19-1 software update, the Gen 4 displays no longer require the operator to accept for remote view

REDUCE THE RISK OF DATA LOSS BY WIRELESSLY SENDING AND RECEIVING DATA

Gen 4 applications and subscriptions allow data to be transferred from the display to the John Deere Operations Center for job reporting and analysis using Wireless Data Transfer (WDT) or Data Sync.

With WDT, you can manually send data to the John Deere Operations Center for review.

Data Sync automatically sends your data to the Operations Center, avoiding the need for manually exporting the data.

Wirelessly sending data helps you save time and money while increasing productivity. Wirelessly transfer setup, prescription, and documentation files securely between office, mobile devices, and 4640/4240 Universal Display or 4600/4200 CommandCenter Display, eliminating the need for USB transfer. This increases your uptime and productivity, reduces the risk of data loss, and enables easy data sharing and more timely decision making.

Through the John Deere Operations Center, you are in control and can easily share files with a John Deere dealer and other trusted advisers.

NOTE: For users in areas of poor cellular coverage, data can be exported using a USB flash drive.

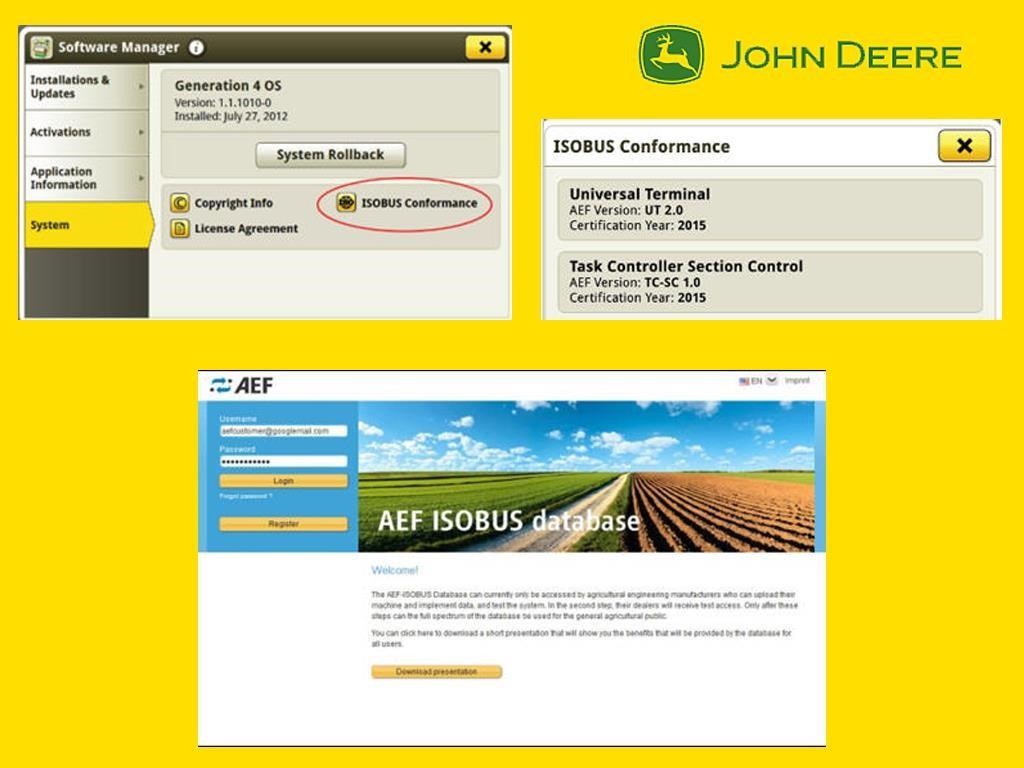

ENABLE TRACTOR-IMPLEMENT COMMUNICATION THROUGH AEF ISOBUS TC-SC COMPATIBILITY

The Generation 4 CommandCenter and Gen 4 Universal Displays display are an AEF ISOBUS compatible display.

An easy plug and play between implements, displays, tractors, and other products is required today in daily business. This is why within agriculture and forestry, an industry standard, ISOBUS, is used for communication between these products.

From the ag industry, the Agricultural Industry Electronics Foundation (AEF) was initiated in 2008 to have a common forum among manufacturers to define the ISOBUS standard further, define and conduct ISOBUS tests, accelerate adoption, label compatible products, and to communicate this to dealers and customers. John Deere is one of the seven founding members of AEF and is very engaged in the organization.

To better ensure ISOBUS compatibility, the AEF developed new functionalities, i.e., auxiliaries (AUX) and Task Controller Section Control (TC-SC,) in addition to the well-known universal terminal (UT). They are also the basis for the certification of ISOBUS products. An ISOBUS functionality can be described as an independent ISOBUS product and the concept is extendable for later additions of functionalities.

Gen 4 CommandCenter and Gen 4 Universal Displays support the following ISOBUS features:

4600/4200 CommandCenter and 4640/4240 Universal Display:

- Universal Terminal (UT)

-> ISOBUS sprayer, seeder, planter, fertilizer spreader, manure applicator, and many other implements can be operated through the UT functionality.

- Task Controller Section Control (TC-SC)

-> With TC-SC, ISOBUS compliant implements like sprayers, seeders, planters, fertilizer spreaders, and manure tankers can be used with automatic Section Control.

- Task Controller Basic (TC-Bas)

-> With TC-Bas, documentation with ISOBUS compliant implements in the standard data format of ISOXML is possible. Also, totals like area, amount, etc. are recorded directly from the implement.

- Task Controller geo-based (TC-Geo)

-> With TC-Geo, location-based documentation with ISOBUS compliant implements in the standard data format of ISOXML is possible. Also, Client, Farm, Field, Boundary, Products, Crops (incl. Varieties), Prescriptions, Operators, Tasks, Comments are recorded directly from the implement.

- Auxiliary Control (AUX-N)

-> With AUX-N, additional control elements that facilitate the operation of complex equipment, such as a joystick; also, the capability of controlling implement functions by means of an additional control element.

ACTIVATE GEN 4 DISPLAY SOFTWARE REMOTELY

Over-the-air activations were enabled with the 18-1 software update to the Gen 4 displays. With that software update or newer, a John Deere dealer can send activations to a Gen 4 display without leaving the office. Over-the-air activations also eliminate the need to manually enter long activation codes like was done previously. This also eliminates multiple trips between the cab and the farm office to enter codes and verify completion.

NOTE: Over-the-air activations requires a current JDLink Connect subscription and Mobile Telematics Gateway (MTG). Planter and platform activations and subscriptions cannot be updated over-the-air.

4200 SECTION CONTROL ACTIVATION

Reduce overlap and minimize skips ensuring precise placement of crop protectants and nutrients

Reduce product overlap by approximately 4.3 percent

Improve performance with tuning, plant-to-row, and boundary features

Reduce operator fatigue so they can stay in the field longer

*Based on independent university study of results with and without Section Control.

Results will vary based on conditions, planter size and type.

FEATURES

OPTIMIZE PRODUCT PLACEMENT WITH GEN 4 SECTION CONTROL

Section Control improves placement of agricultural inputs and reduces operator fatigue by automatically turning implement sections on and off. By reducing product application overlap, Section Control decreases the total amount of product used in the field, lowering the input costs for your operation. Additionally, an increase in yields can be seen as there is less competition amongst plants who may suffer in overlapped areas of the field where the seed population is too high. Some crops can be easily harmed by excessive chemical or fertilizer applications that negatively impact the yield potential of the crop.

Section Control also reduces your stress level, as you no longer need to focus on manually turning the implement sections on and off. This helps reduce fatigue, enabling you to run longer hours when time is of the essence. Section Control puts your mind at ease as less experienced operators get behind the wheel knowing that your product will be placed where intended.

Section Control improves efficiency of producers by:

Reducing seed costs by an average savings of 4.3 percent

Optimizing yield by preventing double application of seed that studies suggest reduces inputs between 1 to 12 percent yield loss

Reducing operator fatigue, allowing for more operational hours in the field

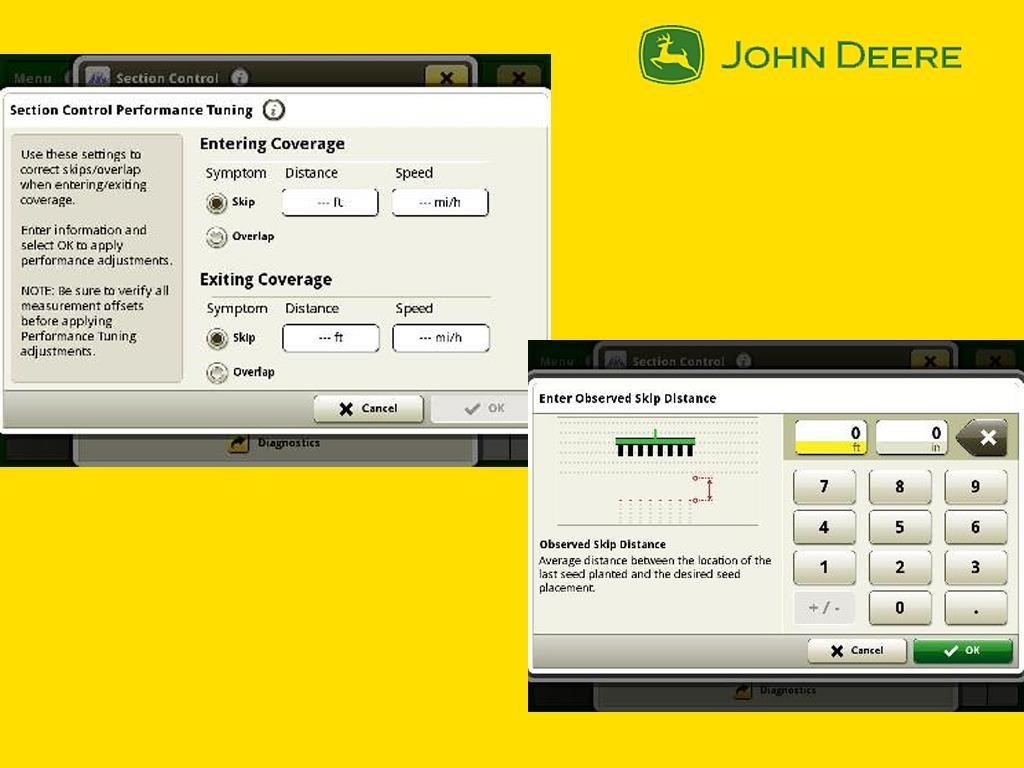

ENHANCE PERFORMANCE WITH TUNING, PLANT-TO-ROW, AND BOUNDARY FEATURES

Get the best use of Section Control with performance tuning, which enables you to tune the planter mechanical delay on and off times so seed is placed at the intersection of two perpendicular passes. Correct skips and overlaps during entry and exit by setting the appropriate on/off time adjustments when entering distances and operating speed in the Section Control application. The application then makes the necessary changes to the system.

Once the system has been tuned, you can visualize the mechanical delay turn on/off times so that driving performance can be seen and better understood. For example, if there are acceleration changes when coming into or out of coverage, it can impact the look-ahead times to properly turn the seeder on or off, which can lead to more overlap or gaps in seed coverage. This additional visualization provides feedback to the operator on how the system is functioning and when the planter is turning on or off.

In addition to tuning, plant-to-row functionality enhances your field performance by allowing you to customize the in-line skip or overlap observed at the intersection of a perpendicular planting pass. Default Performance Tuning settings command the planters mechanical delay times to place seed at the intersection of the last outer headland row, but skip or overlap settings can be customized to meet the specific needs of your operation. For example, producers who want a 15.2-cm (6-in.) skip to allow the corn head snout to pass between rows would set a 15.2-cm (6-in.) skip within the Seed Placement Settings.

Section Control is also capable of preventing application of inputs outside of a field boundary, inside an interior field boundary, or outside of a headland boundary.

Enabling headlands allows operators to plant the headlands after the interior of the field has been planted.

Turning boundaries off provides operators with the flexibility to apply product outside of the field boundary while continuing to use the boundary for field totals, documentation, or field location.

IMPROVED EASE OF USE WITH GEN 4 SECTION CONTROL ADDED FEATURES AND FUNCTIONALITY

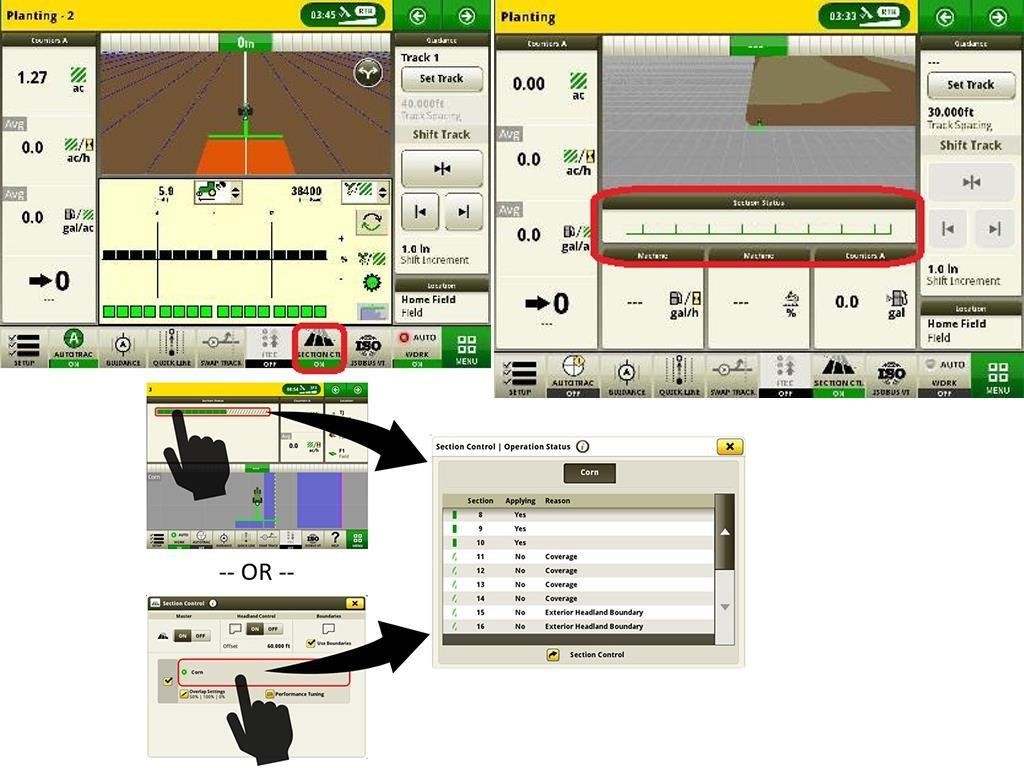

An on/off shortcut key section status module allows you to quickly turn Section Control off for manual operation from any run page.

Place the section status module on any run page to monitor Section Control performance on any screen with different layout options.

Monitor individual section statuses with the diagnostics table, allowing you to understand if a section is on or why the section is commanded off.

SECTION CONTROL TURN ON/OFF TIME VISUALIZATION

Optimize driving patterns to reduce or eliminate operator-caused skips, gaps, or uneven performance across the width of a Section Control enabled tool. Operators cause variability in performance with changes in driving while Section Control commands the tool to transition between on/off. Speeding up, slowing down quickly, or changes in direction of travel result in undesired Section Control performance. Enabling the Section Control visualization within advanced settings allows operators to confidently make driving changes knowing the impact to their operation.

OVERLAP CONTROL

When used in a combine or other harvesting equipment, Overlap Control automatically reduces the header width when harvesting over previous coverage. Reducing the width over previous coverage enables for more accurate area and yield information. In cases where crop has drowned out or is unable to be harvested, Overlap Control allows for sections or rows of the header to be manually be turned off.

Similar models may be shown in addition to the featured model. Equipment may be shown with options. Specifications are subject to change without prior notice.

Express Financing Get Pre-Approved

Get a FR8Star Shipping Estimate