HydraFlex™ Draper - RDF35 Back

- Harvest crops as close as possible to the ground with the HydraFlex™ cutterbar

- Minimize grain loss with a two-speed center feed section

- Enable higher harvesting speed without sacrificing cut quality with a 4” double cut, dual drive, shaft driven cutterbar

- Get more done by eliminating header calibrations

Overview

Increase grain in the tank with a two-speed center feed section. A slow-speed setting softens the impact of crop fingers and drum flighting when engaging with crop. This ensures that easy-shelling crops like lentils and soybeans do not get thrown over the feeder house. Use the high-speed setting in canola or high-yielding cereals to prevent slug feeding while ensuring that the drum does not plug.

Benefits

- Experience less downtime during harvest related to unplugging the header, which allows for more harvesting time at the highest productivity levels.

- Higher feed drum torque is matched to the capacity of the combine to ensure optimal feed rates into the combine. Higher torque on the front feed drum allows operators to confidently harvest tough feeding crops like canola.

- Additionally, prevent underfeeding in light crops with the center crop flow divider. When not harvesting crop with the full width of the draper, the center crop flow divider prevents crop from skipping over the center feed section and going on the opposite draper belt.

Toolless shifting on the gearcase

Toolless shifting on the gearcase

Center crop flow divider

Center crop flow divider

Additional details

- The two-speed center feed section maintains a consistent ratio between the feed drum and center feed belt speed.

- Change center feed section speed with a toolless, two-speed, easy-shift handle on the gearcase to the left of the draper feeder house opening.

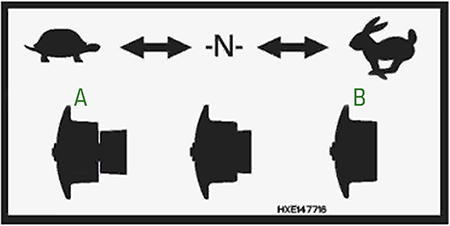

Two-speed center feed section (A is pulled out and B is pushed in)

Two-speed center feed section (A is pulled out and B is pushed in)

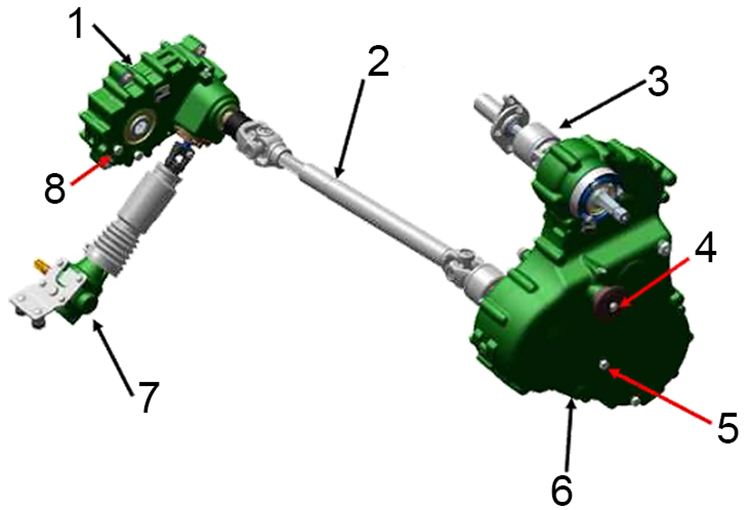

Parts of the two-speed center feed section

Parts of the two-speed center feed section

- Feed drum gearbox

- Center feed drive shaft

- Knife drive shaft

- Center feed speed control

- Oil check

- Main gearbox

- Center belt gearbox

- Oil check

|

Low speed |

High speed |

Feed drum |

200 rpm |

240 rpm |

Center feed belt |

1000 rpm |

1200 rpm |

|

RDF |

HDR |

Feed drum torque |

1217 lb-ft (1650 Nm) |

2109.4 lb-ft (2860 Nm) |

Center belt width |

70 in. (177.8 cm) |

79.1 in. (200.9 cm) |

Overview

Achieve superior ground following when harvesting in a wide range of terrains, crops, and conditions with RDF HydraFlex Draper Platforms. HydraFlex is an industry-exclusive hydraulic float system.

HydraFlex draper system floats with the terrain

HydraFlex draper system floats with the terrain

Benefits

- Float closely to the ground over changing conditions by controlling the cutterbar ground pressure from the cab – simply adjust the armrest knob to vary hydraulic pressure in the float arm hydraulic cylinders.

Hydraulic float arm

Hydraulic float arm

Adjust ground pressure by changing hydraulic pressure in the float arm cylinders

Adjust ground pressure by changing hydraulic pressure in the float arm cylinders

Additional details

- The hydraulic float system features a 7.5-in. (19-cm) float range.

- To lock out the HydraFlex draper into rigid mode, the operator should increase the float pressure to maximum

Overview

Help bushy crops, especially heavy canola, feed evenly into the feeder house with an optional 18-in. (45.7-cm) top auger extending the full width of the draper.

RDF top auger

RDF top auger

Benefits

- With the crop tucked under the auger, the handoff to the center feed drum enables smooth and consistent feeding to the combine to ensure constant load.

- Achieve smooth headfirst feeding when auger speeds are running slightly faster than the belt speed.

Additional details

- This optional 18-in. (45.7-cm) hydraulically driven top auger has an easy speed adjustment at the right side of the platform.

- It is recommended for operation in bushy or high-volume harvesting conditions such as canola.

- Augers can be turned off for crops like lentils or wheat where they are not recommended.

35 ft

4 in.

S-Series Combine: 490 cycles/min

Cutterbar vertical flex: 190 mm

7.5 in.

35 ft

4 in.

S-Series Combine: 490 cycles/min

1.5 in.

42 in.

28.3 in.

14.1 in.

16 in.

40 in.

Center belts: 177.8 cm

70 in.

39.8 in.

0.75 in.

3.3-11.5 fps

Center belts: 211 m/min

692 fpm

Low-speed center belt (fixed): 4.2 m/s

13.8 fps

High-speed center belt (fixed): 5.1 m/s

16.7 fps

16.3 in.

Diameter: 16 mm

0.625 in.

6 in.

High speed: 240 rpm

18 in.

38.05 ft

9 ft

38.05 ft